From Ahmedabad to TCBL: an evaluator’s perspective on the Institute’s work in the textiles sector

From Ahmedabad to TCBL: an evaluator’s perspective on the Institute’s work in the textiles sector

Posted

11 April 2017

Post by Kerstin Junge

Papers relating to the Tavistock Institute’s work in the cotton mills have now been catalogued as part of the Tavistock Institute Archive Project and are available for research at Wellcome Library. The archive covers the experimental reorganisation of weaving in both Indian and American cotton mills, from the perspectives of A K Rice and Eric Miller working in the field. Records include project papers, detailed field notes, research material and data, and correspondence.

Clothes are something we put on every day. And yet, most of us pay little attention to who makes them, the raw material, skills and technology needed to produce them, where they are made, and the waste that is generated by making and buying clothes.

One of the most exciting projects I’m currently working on at the Institute is concerned with exactly those questions. The textiles and clothing business lab project (TCBL), a Horizon 2020 European R+D (but really action research) project, wants to transform the European textiles sector from one that is driven by unsustainable practices (e.g. use of chemicals and over-production) to one that is innovative, knowledge driven and hence more socially, environmentally and economically responsible. We are working as part of a large European partnership made up of organisations from the textiles sector, technologists and academics who are developing social and technological interventions into the textiles sector in order to achieve this fundamental and large scale change.

A recent Institute lunchtime talk by my colleague Camilla Child explored the potential of new applications of socio-technical thinking and put me in touch with the early Tavistock work in the textiles sector (Rice’s Ahmedabad Experiment of the early 1950s and Eric Miller’s follow up in the 1970s). Rice first went there as a consultant to work with Jubilee Mill to address a productivity problem: though automatic looms had been installed these had not resulted in any improvements in performance. A second experiment a few years later took place at a different mill (Calico Mill) which wanted to enter the export market, including the mass-production garment industry, which required continuous pieces of flawless cloth (so a quality challenge needed to be addressed). Two further experiments followed. At Jubilee Mill Rice initiated a worker led re-design of the cloth manufacturing process using socio-technical design principles: a re-design of roles and associated pay to align functions and responsibilities with new technologies; the creation of groups of workers each responsible for a set of looms; flexibility of task allocation within these groups instead of a rigid division of labour between categories of workers; bonuses which rewarded group performance ( quantity and quality of cloth produced). This design was replicated in the other three sites during the 1950s and 1960s. Changes in performance (measured in efficiency and quality of cloth) were captured longitudinally between 1954 and 1970. Across all sites, the re-design led to performance improvements which were still observable in the 1970s in all but one of the four sites.

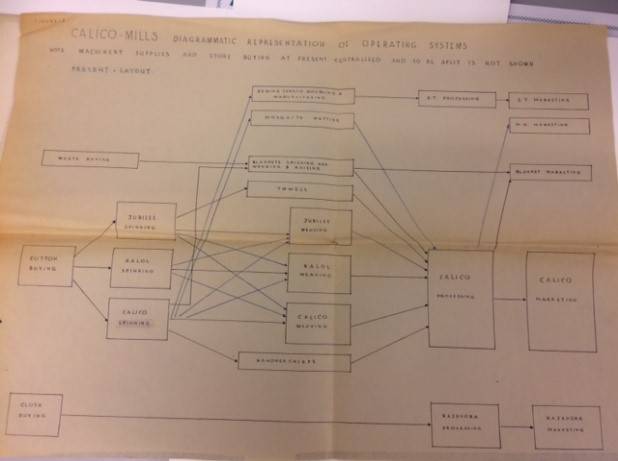

Calico Mills, Catalogue ref. SA/TIH/B/2/4

Had Rice and Miller been evaluators they might have thought of this intervention and their subsequent analysis as informed by a realist tradition. Realist evaluators argue that the context within which an intervention is implemented triggers particular mechanisms (behavioural responses) that are responsible for explaining the observed results (so-called Context –Mechanism – Outcome configurations). So the context for the work re-design in the Ahmedabad experiments – defined as the organisational setting, the bottom up design process and pre-existing performance – triggered the mechanisms of flexible task allocation, group reward, cooperation and mutual help which influenced the improved productivity outcomes in the sites. The size effect of these outcomes differed between sites, and in realist evaluation terms variations in organisational contexts will have been the key explanatory factor. Indeed, Miller himself alludes to this by stating: “It is much more plausible to suggest that the effect on performance of introducing socio-technical systems designed for long term viability will depend on whether pre-existing levels of performance were high or low” [p 24]. By the 1970s, the site whose market context had not significantly changed (e.g. ongoing reliable market for the type of cloth woven) had retained both the original work re-design and the improved performance figures. The original CMO configuration still seemed to hold a decade later. At another site, however, the context (most notably the way in which the group process was transferred) was such that the group mechanisms did not ‘fire’ and there was less cooperation within the group, and identification with it. Performance was poorer than at the site of the original experiment.

In TCBL we are possibly also looking at collaboration as a key mechanism for the large scale change in textiles production that the project is looking to achieve: radical innovation is promoted by linking people and organisations with different – and often cutting edge – skills. However, here the collaboration is at a completely different scale: potentially pan-European, potentially a number of organisations across the whole textiles value chain joining up to produce in a more sustainable manner. So work organisation still matters, and the question then is whether and how this can be achieved in a way that produces measureable success (when this success might be initially less tangible or perhaps harder to measure) and hence the economic motivation to scale the new way of working out. So, for us as evaluators charged also with thinking about replication, the learning from the Ahmedabad experiment surely should be that paying attention to roles taken up by actors in the wider TCBL system in relation to the task that is being implemented, observing changes in the work systems created in relation to external context and figuring out how to measure business relevant outcomes would be a promising approach. Thankfully, this is exactly what we are doing, demonstrating in action the power of organisational memory and the timelessness of the early Tavistock work which lives on in both explicit and tacit forms.

The catalogue can be browsed online using the reference SA/TIH/B/2/4 and consulted on site at Wellcome Library by registered library users. More information on joining the Library can be found here: http://wellcomelibrary.org/using-the-library/joining-the-library/

Join Kerstin Junge along with Joe Cullen for a lunchtime talk as they discuss further the work with TCBL. ‘Evaluating Complex Business Ecosystems: the case of the European clothing and textile industry’, 26th April at the Tavistock Institute. Find out more here.